The pandemic has upended our lives in countless ways. One of them has to do with the adoption of new technologies: According to an October 2020 study by McKinsey, use of advanced technology in operations accelerated by a factor of 25 due to COVID-19.

But with the advent of new technologies comes a host of new challenges. One of them is the simple fact that these new operating methods will require new maintenance skills and techniques that most of today’s technicians just don’t have yet.

In this context, it’s never been more important to ensure quick, flexible, efficient training for new maintenance workers. Here are the three main reasons why, plus some tips for getting this training up and running.

Industry 4.0 refers to the growing trend of automation and data exchange between various industrial technologies.

1. We are in Industry 4.0

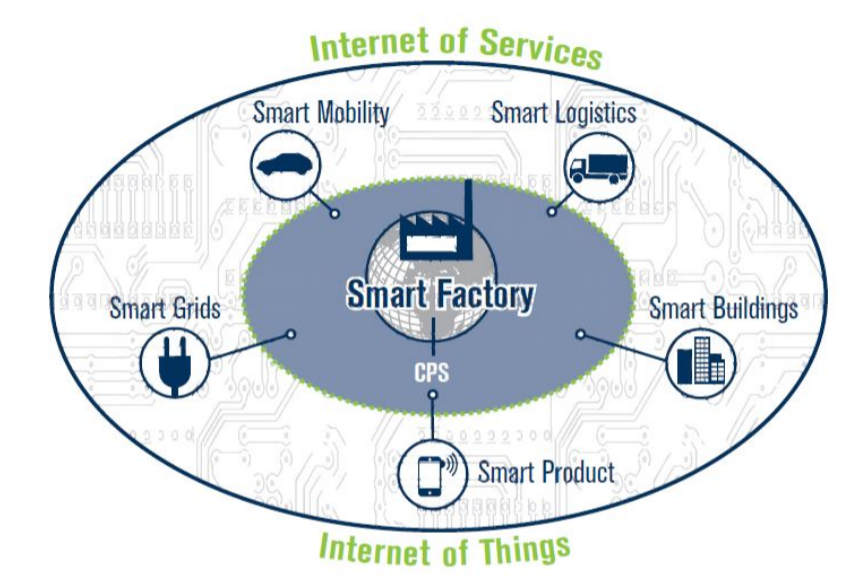

The ‘next industrial revolution,’ otherwise known as Industry 4.0, was formally recognized in 2016 by the German government. It defined Industry 4.0 as the advent of full-scale factory automation and a transition to the ‘smart’ industry. In other words, Industry 4.0 refers to the growing trend of automation and data exchange between various industrial technologies, including the Industrial Internet of things (IIoT), wireless sensors, cloud computing, and, of course, AI and ML (machine learning).

There are four main components of Industry 4.0:

- Cyber Physical Systems (CPS): cooperation between computer and physical machines (e.g. an industrial robot arm)

- Internet of Things (IoT): physical objects that can exchange information with other systems and devices over the Internet

- Internet of Services (IoS): the ability of the system to go online and take advantage of services that are helpful in its domain

The Internet of Things (IoT) and Internet of Services (IoS) are actually prerequisites of the fourth main component of Industry 4.0—the Smart Factory. This refers to a situation where IT systems and software manage the entire production process: they know where each product is at any time, and can start machines depending on the status of the production process.

All in all, the main goal of Industry 4.0 is increased flexibility.

Industrial maintenance 4.0

The natural extension of this fourth wave of industrialization is industrial maintenance 4.0. This area is wide in scope, and includes a holistic approach to all of Industry 4.0’s data and management, ensuring reliable functionality of all assets and optimized asset management.

Implementing components of industry 4.0 into your maintenance operations is not a simple task. In order to be one step closer to the industry 4.0, you will have to prepare your maintenance technicians for the changes that new systems and processes will bring. There are certain measures you can take to make the adjustment process easier:

- upgrade existing maintenance practices

- create standard operating procedures (SOPs) to ensure consistency

- prioritize communication among staff in order to build trust

- provide necessary education and training for your maintenance staff

With the rise of Industry 4.0, the future of work will include new technologies, and therefore new job positions, so manufacturing workers will need to acquire new skills.

For instance, let’s take the example of a wind turbine manufacturer that offers real-time remote monitoring of equipment, and 24/7 access to a diagnostic center. Imagine a scenario where vibration-monitoring sensors in a turbine point out that there’s an anomaly—alarms have been automatically triggered. Those sensor technologies and monitoring systems allow manufacturers to repair equipment before the actual breakdown occurs.

In the above scenario, there wouldn’t be a need for a traditional service technician. Instead, a digitally assisted field-service engineer would be required to address the issue—and that person would need appropriate training.

2. Smart technologies are the solution to preventing future pandemics

“COVID-19 has caused widespread disruption.” That is what Deloitte had to say in a study regarding ‘smart buildings’ undertaken at the height of the pandemic. Deloitte felt that smart building technology was the answer for companies and employees returning to work after a series of rolling lockdowns in most countries. The advice was that companies should turn to smart technology for all their facility needs and, thus, by extension, smart maintenance.

Improved ventilation features of these smart buildings are worth noting; these smart systems could improve occupational hygiene levels and reduce the risk of infectious disease transmission in buildings, through:

- the deployment of ventilation techniques such as air filtering, upper-room ultraviolet germicidal irradiation (UVGI) and white light LED systems;

- air sensors that measure indoor air quality (IAQ); and

- the coordination of data from air sensors with occupancy analytics to optimize ventilation systems in buildings and work areas.

The implementation of these technologies will require a specific combination of skills, from traditional maintenance skills and advanced technical capabilities to the ability to drive the changes of the organization. How can maintenance managers attain the skills that smart technology demands, if they don’t have the correctly trained maintenance personnel?

The answer is upskilling.

Smart maintenance requires an upskilled workforce

Even experienced maintenance workers would probably need to be up-skilled in order to fully implement the types of cutting-edge solutions that will be part of the Industry 4.0 future.

However, according to the Manufacturing Workforce Report, three out of five manufacturing workers said their organization is not providing proper training and development for its employees. Don’t be one of those organizations. Instead, put the focus on regular training and development of your maintenance workers. Otherwise, you’ll experience unnecessary downtimes.

Except for some regular maintenance certifications, future maintenance workers will need to acquire knowledge related to data-driven maintenance. They will have to master the methods and get acquainted with the systems to manage maintenance proactively based on data. And, they’ll have to contend with increased demand for production.

3. Production is increasing all over the world

One notable paradox of all the upheaval caused by the pandemic is the upsurge in production across many industries, a result of the dramatic rush to get back to business and recharge economies.

For example, studies in 2021 showed that manufacturing activity hit its highest level in 37 years in the United States, and many businesses are scrambling for qualified workers to fill much-needed skilled positions, including ones in the maintenance industry.

Increased production doesn't mean only your staff have more work to do, but the machines as well, and more frequent maintenance of your assets is required. What can you, as a manufacturer, do to keep up? Well, there are a few steps:

- upskill maintenance technicians, so they can take over more complex maintenance tasks

- create new or upgrade existing maintenance procedures and define a more efficient workflow

- implement and utilize software

- train your maintenance staff better, so they can finish tasks sooner than expected

The best course of action to train maintenance staff

There’s already a large deficiency of workers in the manufacturing sector and, unfortunately, the future is not bright. Deloitte predicts a shortage of 2.1 million workers by 2030, which means that manufacturers should put the focus on the workforce they already have and provide them with proper maintenance training and onboarding programs.

Another crucial step is to create clear procedures and checklists workers can use when needed. For example, it would be good to have Standard Operating Procedures (SOPs)—documents consisting of detailed instructions that outline how to perform a specific task. That way, the whole team can stay consistent.

As we already mentioned, communication with and among maintenance staff should be a priority. Managers must practice open communication with the staff and involve them in the process of implementing new technologies, including holding toolbox meetings where they could exchange experiences and best practices. Also, make sure to mix senior workers with less experienced ones in the same shift. That way, the less experienced staff can take the advantage of the seniors' knowledge and experience.

Last but not least, think about embracing a Collaborative Learning approach to training where employees learn with and from each other, in the flow of work.

Discover the key to 90%+ engagement rates

By providing your contact info, you agree to receive communications from 360Learning. You can opt-out at any time. For details, refer to our Privacy Policy.